Description

MACRO IRHD SYSTEM

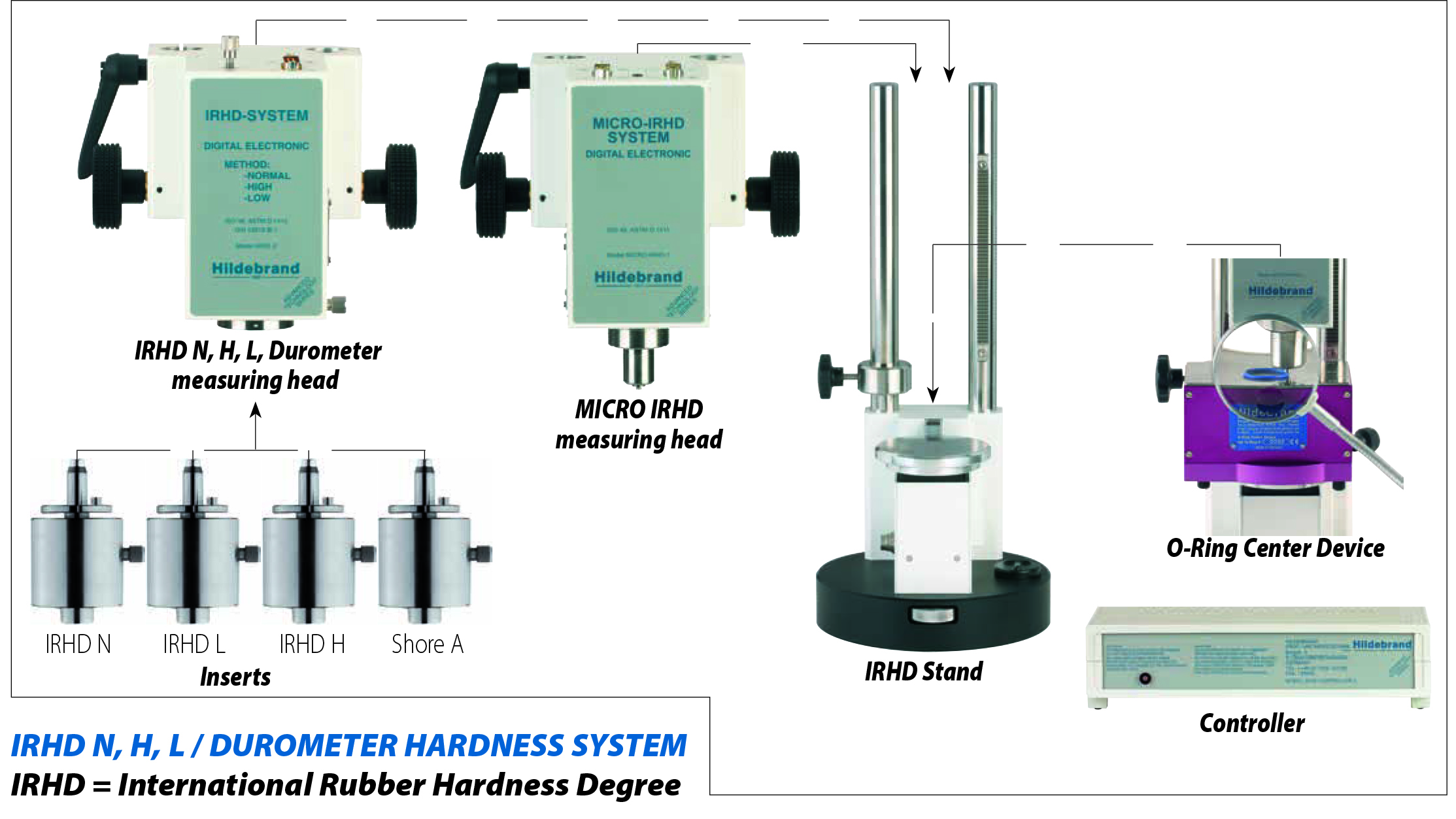

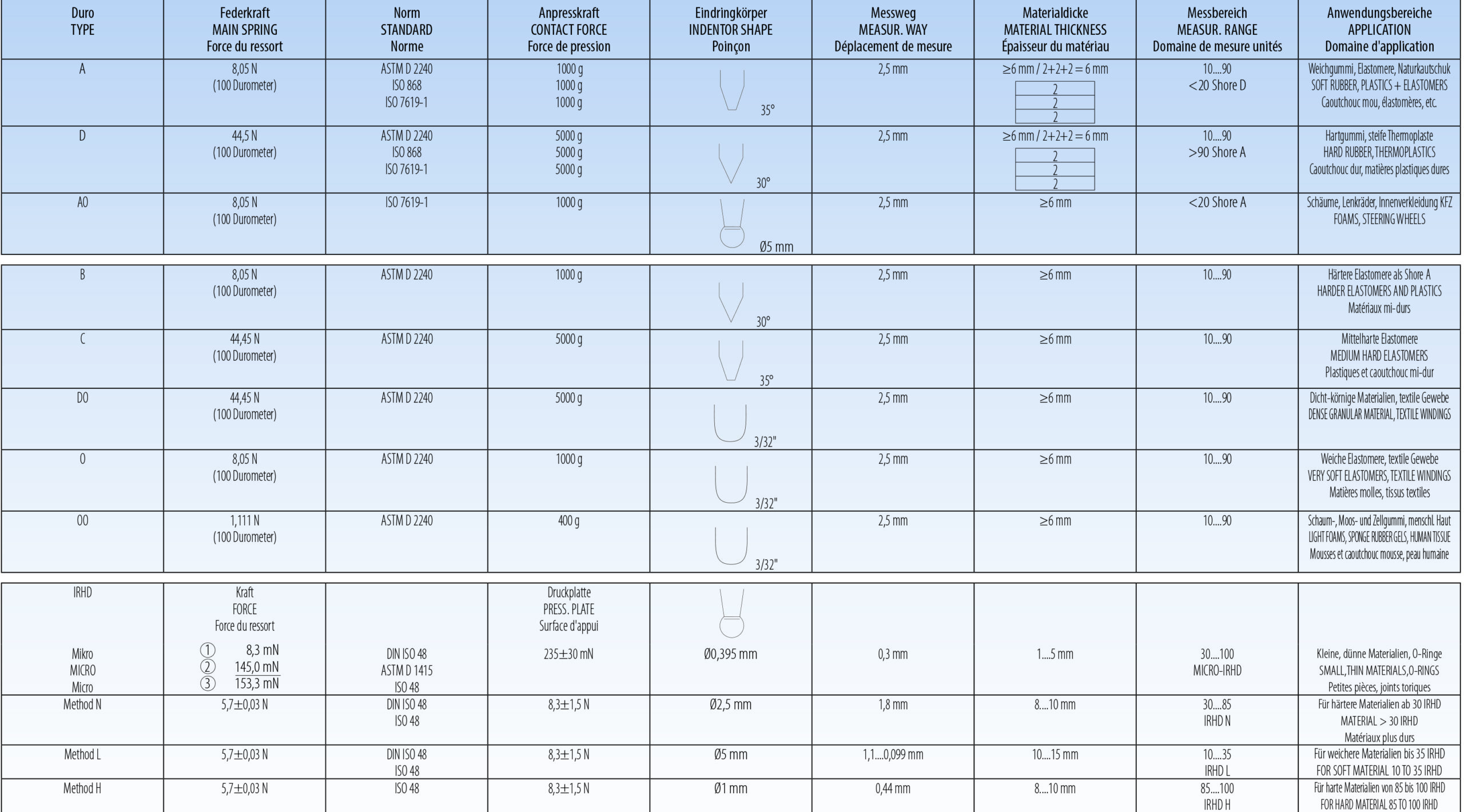

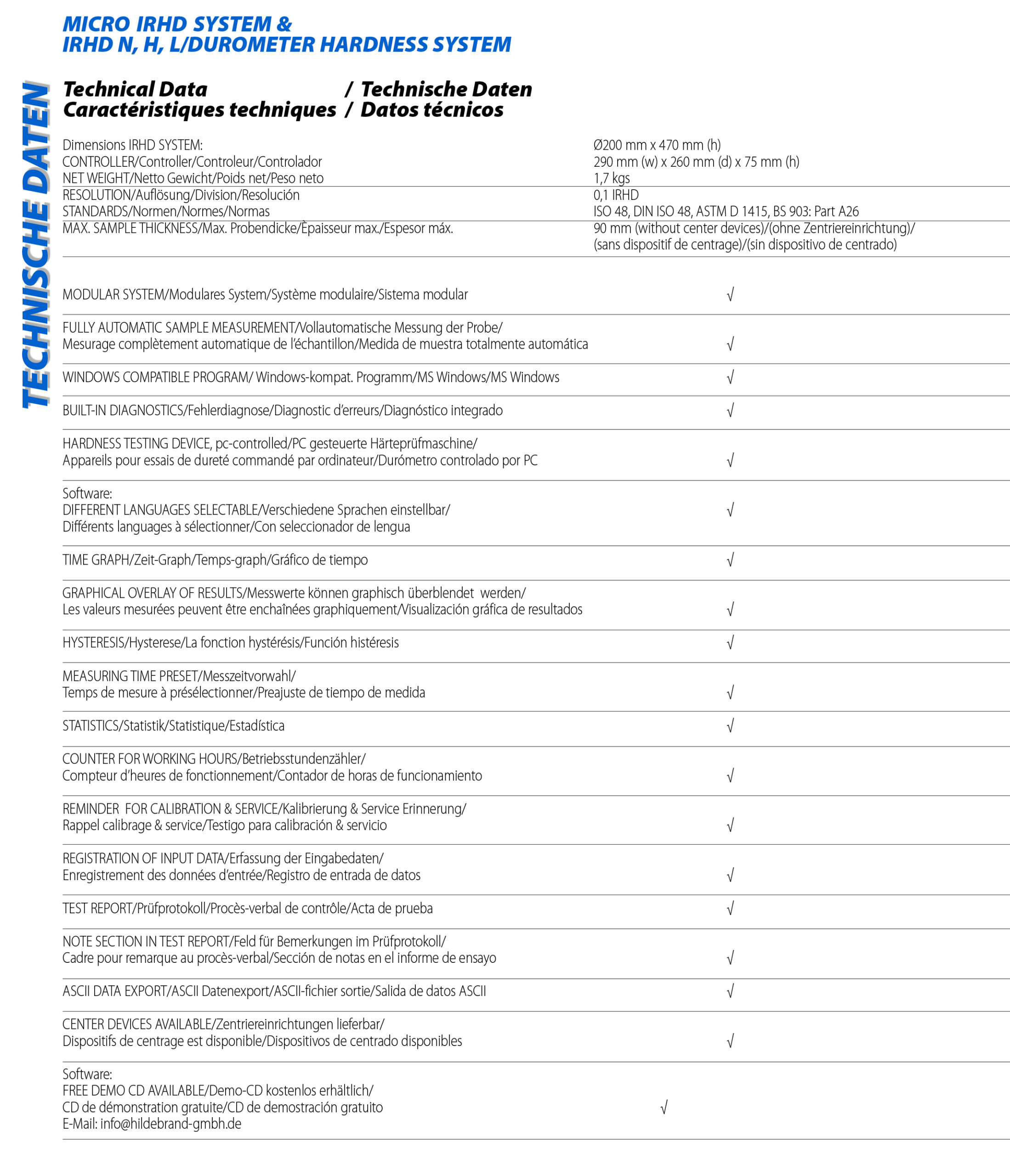

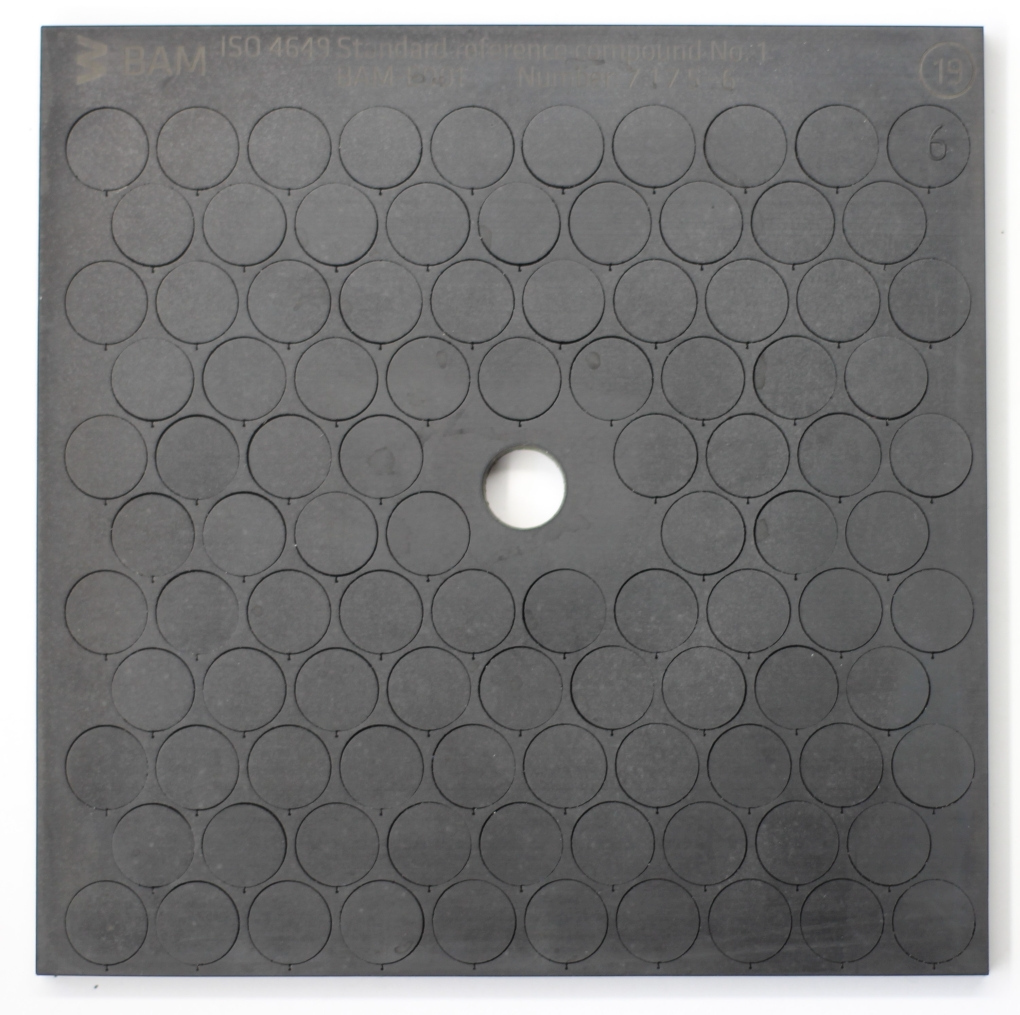

The patented IRHD N, H, L / Durometer Hardness System provides hardness readings on elastomers and plastics with a specimen thicker than 6 mm according to IRHD and Durometer hardness. It complies to international standards DIN ISO 48, ISO 48, ASTM D 1415 and DIN ISO 7619.

Available inserts for IRHD: ball dia. 2.5 mm, 5.0 mm, 1.0 mm and for Durometer A.

You can fit the inserts without tools into the measuring head. An electronic identification of each insert is housed in the measuring head. The corresponding software for each insert is set up automatically. You cannot mix up the inserts. Therefore this system eliminates operator errors. The patented IRHD N, H, L / Durometer Hardness System is working fully automatically with a PC and the Hildebrand Software. The Software controls the operation of the system. It is working under MS Windows and offers unique features. Hardness value, graph, statistics, test report are only a few features of this software. An ASCII-output file is provided.

The modular construction makes it possible to change the measuring head. An additional measuring head “MICRO IRHD” is available.

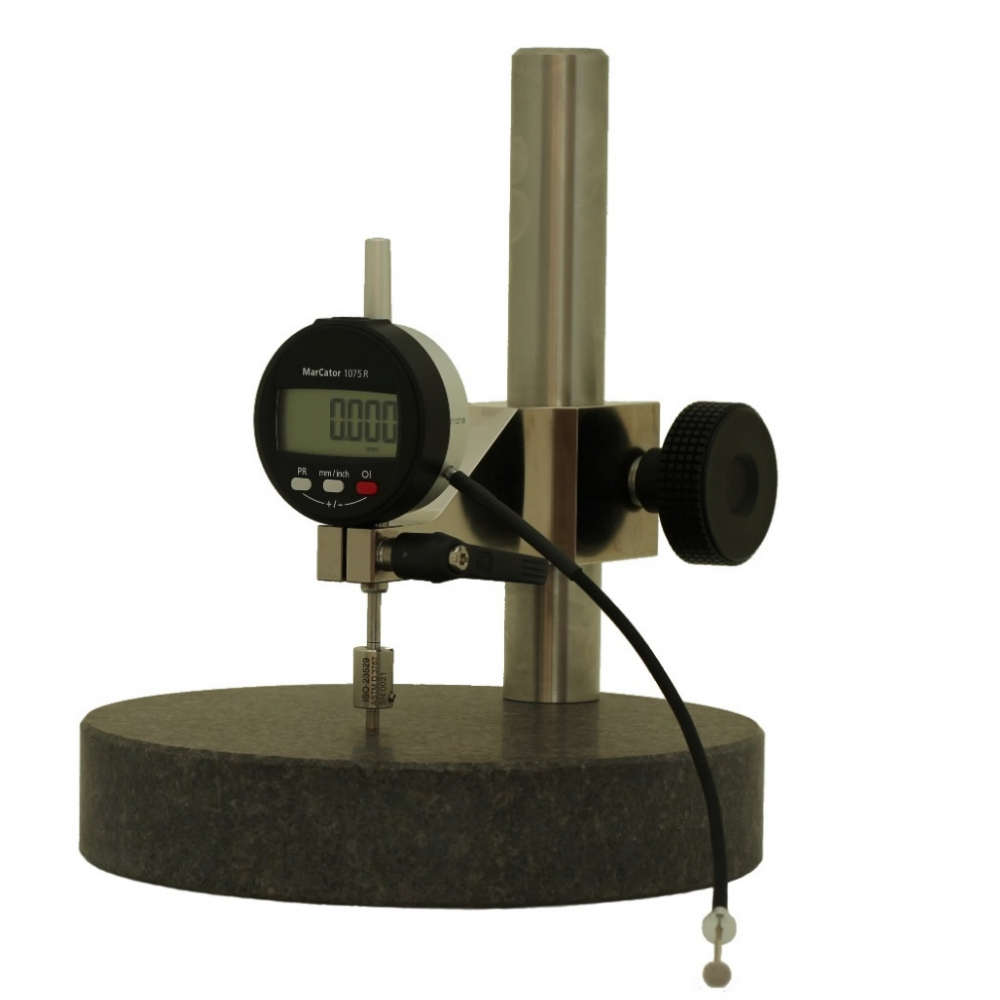

MICRO IRHD:

The MICRO IRHD SYSTEM provides hardness readings on elastomers according to MICRO IRHD. Recommended specimen thickness is 1 to 5 mm. It complies to international standards such as DIN ISO 48, ISO 48 and ASTM D 1415.

The MICRO IRHD SYSTEM is a hardness testing machine controlled by a Hildebrand MS-Windows software. 2 weights are automatically lowered and raised. Thus this system eliminates operator errors while testing. Specimen are positioned on the support table. The table automatically drives to the measuring head. The minor load is automatically lowered to the indenter. This position of the indenter represents 100 MICRO IRHD. The major load is lowered now. The penetration of the indenter is digitally measured after 30 seconds and converted into MICRO IRHD UNITS. Very small forces are used for a max. indentation depth of 0.3 mm of the indentor. O-Rings and seals can be tested by using our automatic O-Ring Center Device.

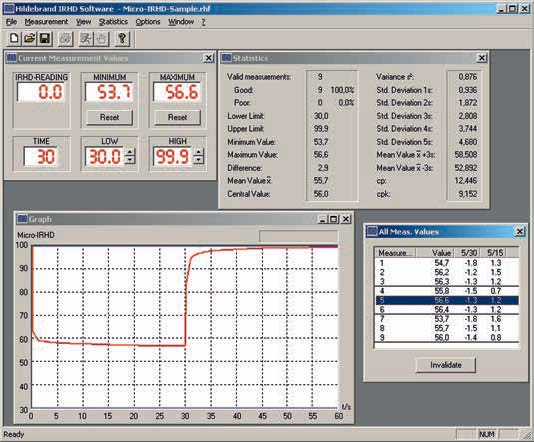

The Hildebrand MICRO IRHD software checks and controls the operation of the system. The software is working under MS-Windows and offers unique features. The hardness value, graph, hysteresis, statistics, test report are only a few features of this software. An ASCII-output file is provided. All data are transmitted to the IRHD Controller, which is connected to the RS 232 interface of the computer.

Guarantee:

All products displayed in this catalogue including their accessories are guaranteed for a period of 2 years against defective workmanship and / or material. This guarantee excludes any damages caused by inexpert handling and it does not apply to products that are etched, stamped or otherwise marked or damaged.

Software:

Our software is state-of-the-art, but in some circumstances we can`t preclude mistakes. Significant software errors detected within 6 months after date of invoice will be corrected properly should they considerably influence the function of the device. Customer-PCs must adhere to the minimum requirements we are demanding in our user’s manual.