Description

THE LINE FEATURES:

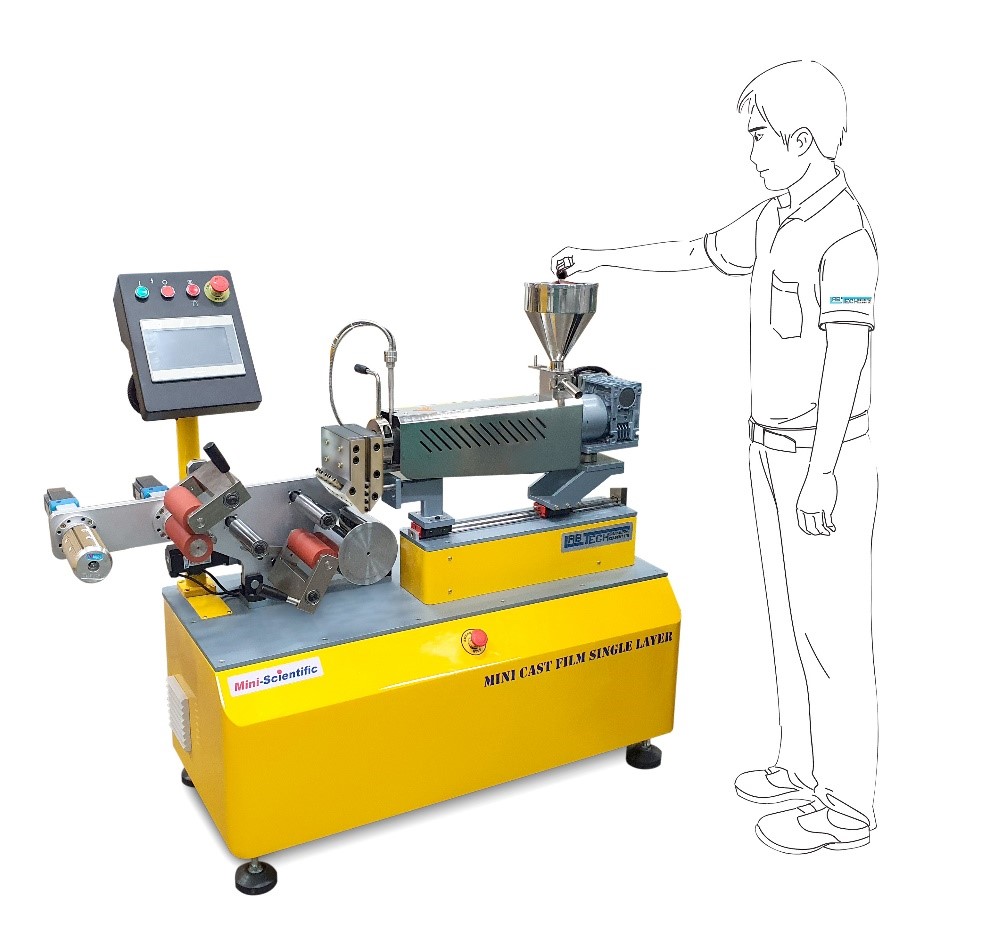

- Mini design taking up a floor space of only 1.5 m x 0.7 m (5.0 x 2.3 ft) and a height of 1.2 m (4.0 ft) make it easy to fit into even the most crowded lab.

- The Mini Extruder can process regular polymer pellets

- The entire assembly is mounted on a sturdy steel subcabinet containing all major supply cables and electric components inside the subcabinet, giving a very clean appearance with very few visible connections to the extruder.

- The mini single-screw extruder is mounted on an elevated base on top of the subcabinet

- The die and the extruder are mounted individually on the same sliding rail, and the die can be separated from the extruder with a quick lock C-clamp. This enables easy removal of the extruder for cleaning and removing of the screw.

- The roll is vertically adjustable so that the gap between the die and the roll can be adjusted to reduce the necking of the extruded melt from the die.

- The rubber pressing roll of the chill roll has a handle that can be swung and securely locked into place away from or towards the roller. In the position where it presses against the chill roll, it serves to ensure that the film is tightly wrapped around the Chill Roll for optimum cooling efficiency. The pressure of this rubber pressing roll is adjustable with a spring-loaded screw

- The film tensioning nip is opened with a handle, and the nip force is adjustable with a spring-loaded screw

- The surface wind-up unit can hold a max film width of 125 mm, and it is equipped with an air expansion shaft holding a 3-inch bobbin

- The chill roll, haul-off nip-roll, and wind-up device are driven by three individual AC servo motors

- The line is equipped with a user-friendly 7-inch full central LCD touch screen unit controlling all functions like:

- extruder temperature and RPM

- die temperature

- chill roll temperature and RPM

- downstream nip-roll and wind-up RPM