Description

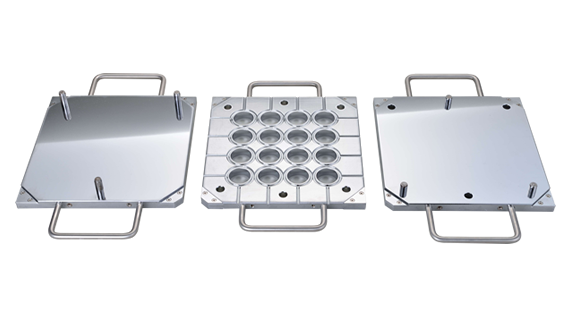

We can also manufacture special-shaped molds in the development stage and custom-made molds that match the characteristics of the material at any time. Our weight reduction and vulcanization molds using hard aluminum (about 1/3 the weight of the conventional type) are also very popular. We can also modify molds that are currently in use.

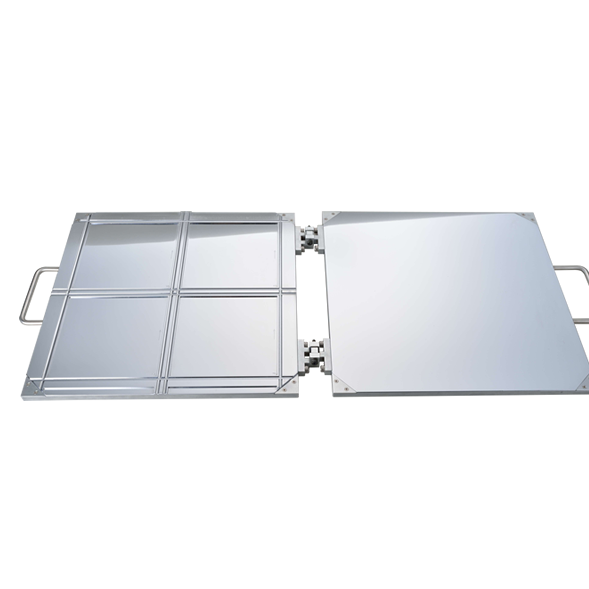

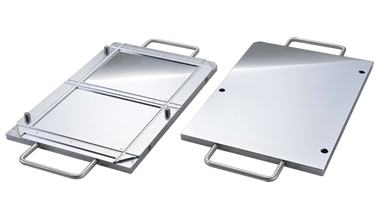

Weight reduction vulcanization mold

Comparison data between lightweight vulcanization mold (hard aluminum/YH75) and conventional type (carbon steel/S55C)

- Lightweight

(About) 1/3 of carbon steel safety improvement, less time required for installation and removal

| Material | specific gravity |

| YH75 | 2.82 |

| S55C | 7.90 |

- Excellent thermal conductivity

Shortening of molding shot cycle (approximately) twice that of carbon steel

| Material | Thermal conductivity |

| YH75 | 0.31 |

| S55C | 0.14 |

- High hardness

Roughly equivalent to carbon steel

- Excellent corrosion resistance

Hardly corroded by resins, rubbers, plasticizers, antistatic agents, release agents, etc.

- High fatigue strength

Ideal for applications where repeated loads are applied , such as (approximately) three times as much as carbon steel

press die materials and plastic die materials

| Material | Fatigue strength (N/m㎡) |

| YH75 | 160 |

| S55C | 60 |

- Other mechanical properties

| Material | Tensile strength (N/m㎡) | 0.2% proof stress (N/m㎡) | Elongation (%) | Brinell hardness (HB) | Shear strength (N/m㎡) |

| YH75 | 570 | 500 | 11 | 165 | 330 |

| S55C | 650 | 390 | 14 | 183 | 340 |