Description

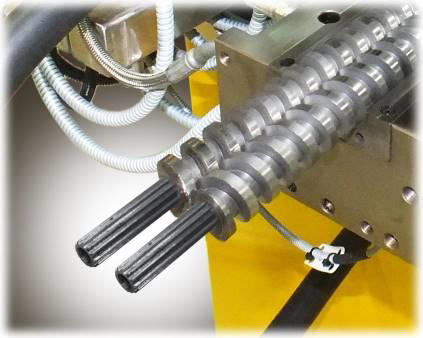

The Scientific COMBI 26 mm Twin-Screw Extruder is a state-of-the-art machine engineered for both co-rotating and counter-rotating screw configurations in a single system. Designed for maximum versatility, it processes PVC powders, pellets, and a wide range of thermoplastics without requiring separate machines.

Its modular clamshell barrel allows rapid access for cleaning, screw changes, and observation, minimising downtime during product changeovers. Interchangeable barrel lining inserts are made from through-hardened tool steel for up to 400 °C processing, with optional stainless steel and PPM steel inserts for enhanced wear and corrosion resistance.

The 15 kW high-torque drive and precision gearbox with forced oil lubrication deliver reliable torque under demanding conditions. Each barrel zone features independent temperature control, with water cooling and electric cartridge heating for stable processing.

The COMBI extruder comes standard with a four-hole strand die, quick-change hopper feeder, and can be upgraded with side feeders, screen changers, and gravimetric dosing systems. Screw speeds reach up to 800 RPM (co-rotating) or 400 RPM (counter-rotating), ensuring efficient throughput for a variety of formulations.

Whether for research laboratories, quality assurance departments, or specialty production, the COMBI 26 mm Twin-Screw Extruder offers the performance, adaptability, and build quality needed to meet the highest extrusion standards.

Specifications

| Feature | Co-Rotating | Counter-Rotating (PVC) |

|---|---|---|

| L/D Ratio | 40 L/D | 40 L/D |

| Screw Speed | 0 – 800 RPM | 0 – 400 RPM |

| Motor Power | 15 kW | 15 kW |

| Max Output Pressure | 300 bar | 300 bar |

| Max Torque @ 600 RPM | 2 × 90 Nm | 2 × 90 Nm |

| Specific Torque | 9.8 Nm/cm³ | 9.8 Nm/cm³ |

| Max Barrel Temp | 400 °C | 400 °C |

| Heating Power per Barrel (4 L/D) | 2.0 kW | 2.0 kW |

| Cooling Requirement | 3 bar / 20 L/min | 3 bar / 20 L/min |

| Min Batch Size (LDPE) | 1,000 – 1,500 g | 1,000 – 1,500 g |

| Pellet Feed Size | 3 × 3 mm | 3 × 3 mm |

| Net Weight (40 L/D) | 1,000 kg | 1,190 kg |