Description

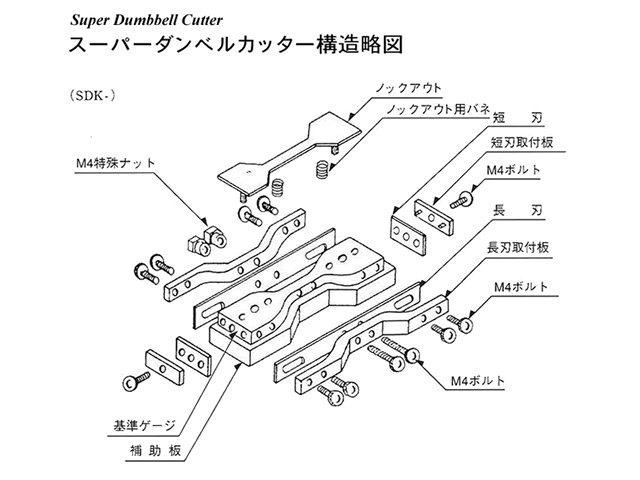

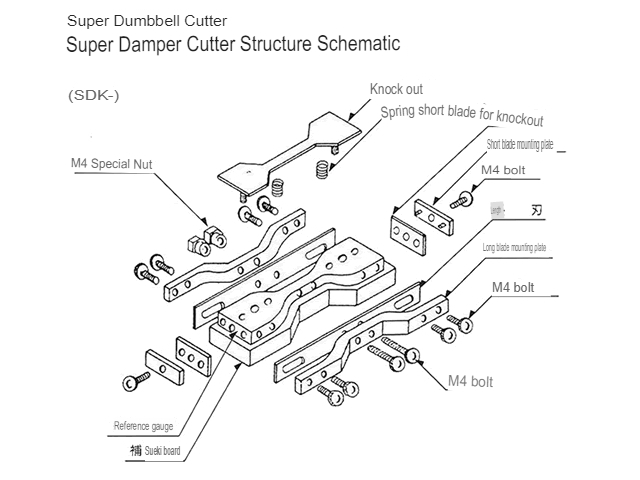

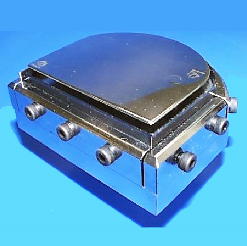

The Super Dumbbell® has a spring type ejecting device that ejects a cut test piece instantly with ease. Furthermore this device, called “Knock Out Device”, sticks out a little bit from the edge of blade usually, which prevents to touch the edge accidentally making sure safety work.

The most remarkable merit of the Super Dumbbell is its excellent cutting performance that is realized by strict manufacturing ® quality control. Thanks to special grinding method, it can minimize undesirable effects, such as crack and burr that may happen quite often with the cut test piece.

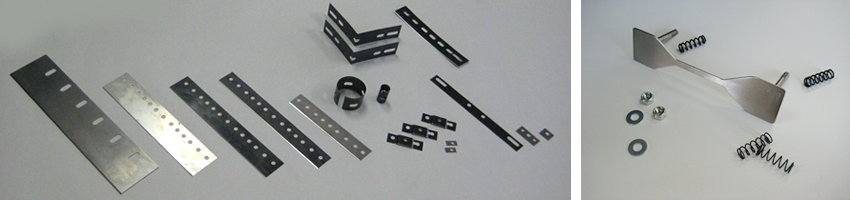

Left: Spare blade for Super Dumbbell R (example) Right: Spring-type pushing mechanism (example)

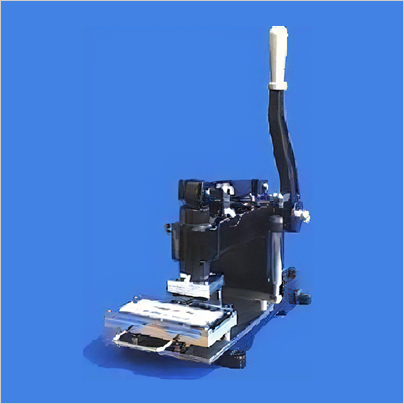

Super Dumbbell Cutter

SDK-500 (JIS K6251-5, K7113-2, ISO37-1 ,JIS K7127 Type 5, etc.)

SDMBK-1000N (JIS K6252 Angle Shaped with nick, ISO 34-1 Angle type with incision); SDMAK-1000 (JIS K6252, ISO 34-1 crescent type, etc); SDMBK-1000 (JIS K6252, ISO 34-1 Angle type without notch)

SDMP-1000 (JIS K6251-7, ISO 37-4, DIN 53504-S3, etc.)

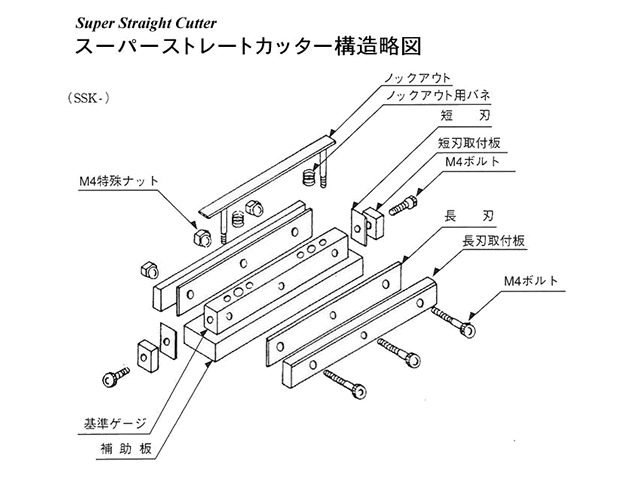

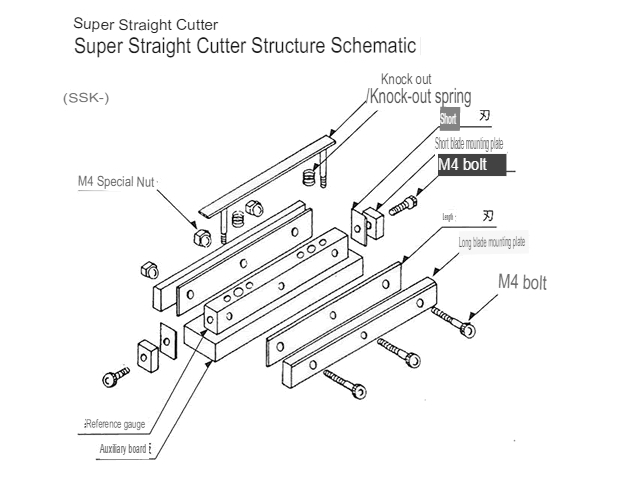

Super Straight Cutter

SSK-1000 (15 × 60 mm)

Super Straight Cutter (Custom-made size)

Super Round-shaped Cutter

Super Round-shaped Cutter (Custom-made size)

SDRK-1000 (ASTMD1922 for Elmendorf tear test piece)

FEATURES

● A set of Super Dumbbell® includes standard accessories [5 sets of replacement blades, standard tools, spare bolts and nuts].

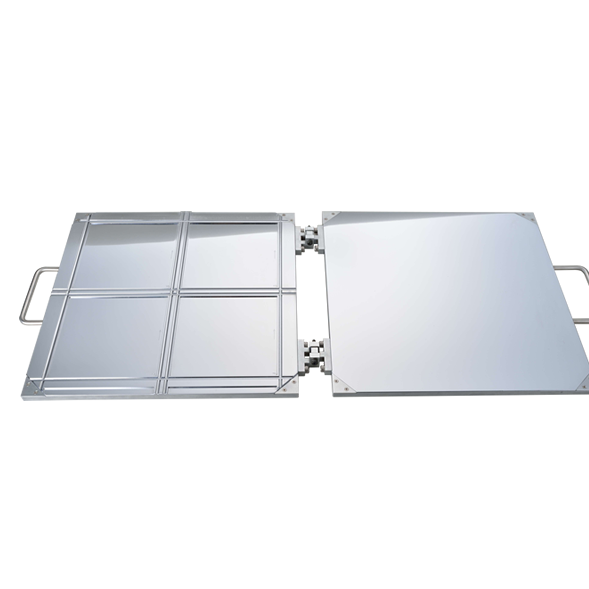

● Various types of replacement blades are used according to the shape to be punched and the characteristics of the sample to be punched.

● The Super Dumbbell® has a built-in spring-type push-out mechanism (knockout mechanism), which enables easy and quick removal of samples after punching.

● In addition, since the spring-type push-out mechanism protrudes from the cutting edge during normal operation, it is difficult for fingers to directly touch the cutting edge, which is also safe.

● When ordering, please specify the dimensions of the cutter mounting part or the name of the press manufacturer.

Standard boss (mounting part) processing cost is included in Super Dumbbell R1 type.

Please let us know if you need a special boss. (Special boss, price separately)

● Many cutters of various standards are available.

[JIS, ASTM, DIN, ISO, BS, IEC, UL, etc.]

● In addition, we can manufacture cutters of various shapes according to the specified dimensions.